Fossils preserve ear of prehistoric whale, says new research

Fossils unearthed in a South Carolina drainage ditch are providing insight into the development of ultrasonic hearing in prehistoric whales, a...

Comet crashes and burns as it passes the sun [Video]

On Thursday, NASA released a video captured by an international solar observatory that showed a comet getting vaporized by the Sun.

The...

Masaya Volcano Is Going To Be Connected To The Internet

Cossman will descend 1,200 feet into the volcano, named Masaya, in order to test the Internet.

American multinational conglomerate GE teamed up...

Security cam captures unexplained light over Gateway Arch

More video of an odd light appearing over the Gateway Arch has been posted to social media.

Security-camera footage from Malcolm W....

Milky Way’s core is a cosmic desert with no new stars, scientists discover

Scientists have reportedly discovered the most-desolate place in the Milky Way. The vast expanse right at the centre could well be...

New research finds last woolly mammoths died of thirst

A new study in the Proceedings of the National Academy of Sciences suggests the last woolly mammoths died out because they...

Hawaii volcano shows ‘smiley face’ during eruption (Viral video)

A videographer has captured a stunning image of volcano eruption in Hawaii which clearly looks like a smiley face.

The Kilauea volcano...

Asteroid to Hit Earth: NASA is Ready

Nasa is planning to launch a probe to collect rock samples from an asteroid which may one day it hit Earth.

The...

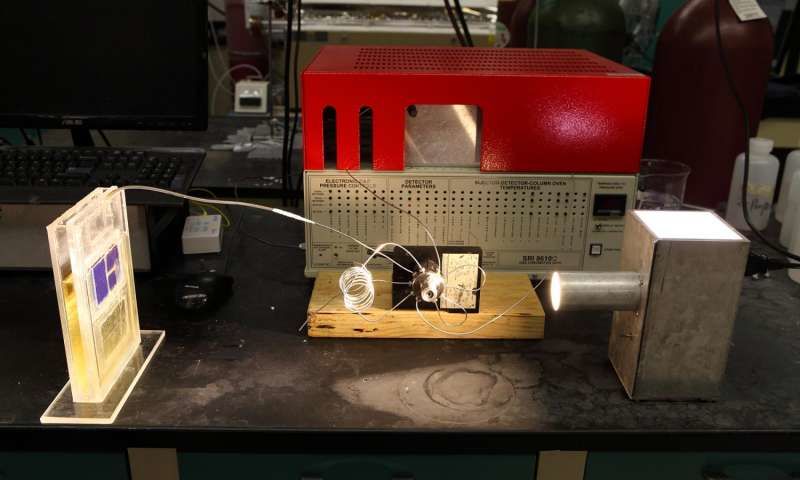

New Leaf: Scientists turn CO2 into fuel with solar power

An "artificial leaf" device featuring solar cell technology that can convert and recycle atmospheric carbon dioxide into hydrocarbons could lessen dependence...

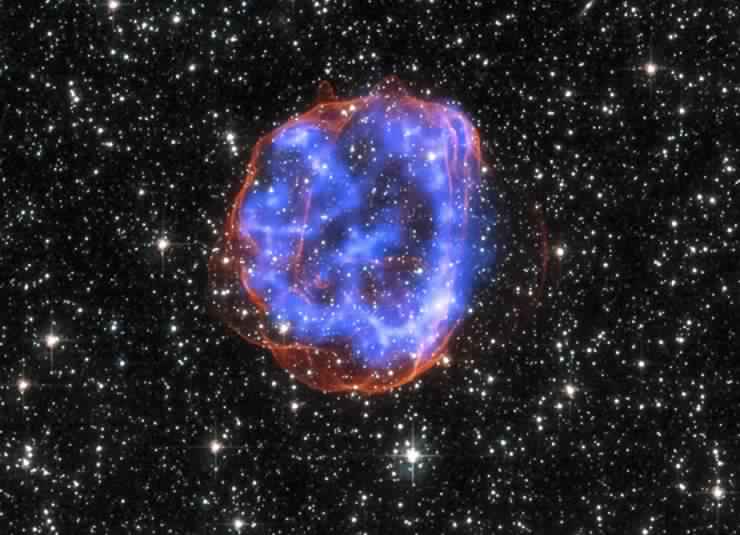

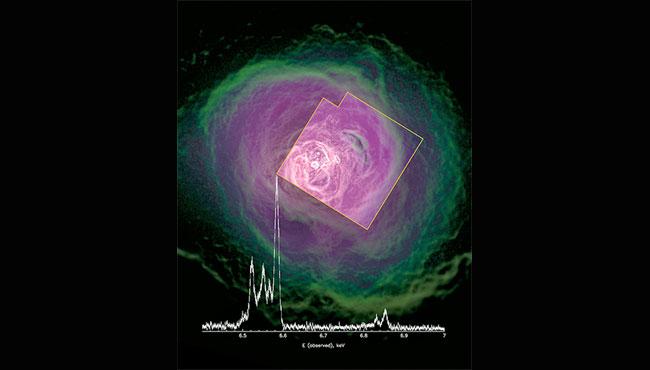

Hitomi satellite found slow gas flows in galaxy cluster

The Hitomi X-ray astronomy satellite detected, before it lost contact with Earth in late March, that superheated gas at the center...

![Comet crashes and burns as it passes the sun [Video] Comet crashes and burns as it passes the sun [Video]](https://webtopnews.com/wp-content/uploads/2016/08/Comet-crashes-and-burns-as-it-passes-the-sun-Video.jpg)